- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

SLJ-EC-250

Product Description

Basic Info.

| Condition | New | Application | Use for handling,palletizing, loading and unloading in production lines. | |

| Type | Jib crane-Electric hoist | Capacity | 100-2000kg, Customized | |

| Up and Down Stroke | 0-2000mm, Customized | Working Radius | 3000mm, Customized | |

| Max Height | 3500mm, Customized | Basic Design | Clamping, Lifting, Rotating | |

| Installation Form | Ground Installation, Customized | Specification | Customized | |

| Transport Package | Wood Box | Origin | China | |

| Trademark | Escott, or customized | Production Capacity | 100 pcs/Month |

Product Introduction

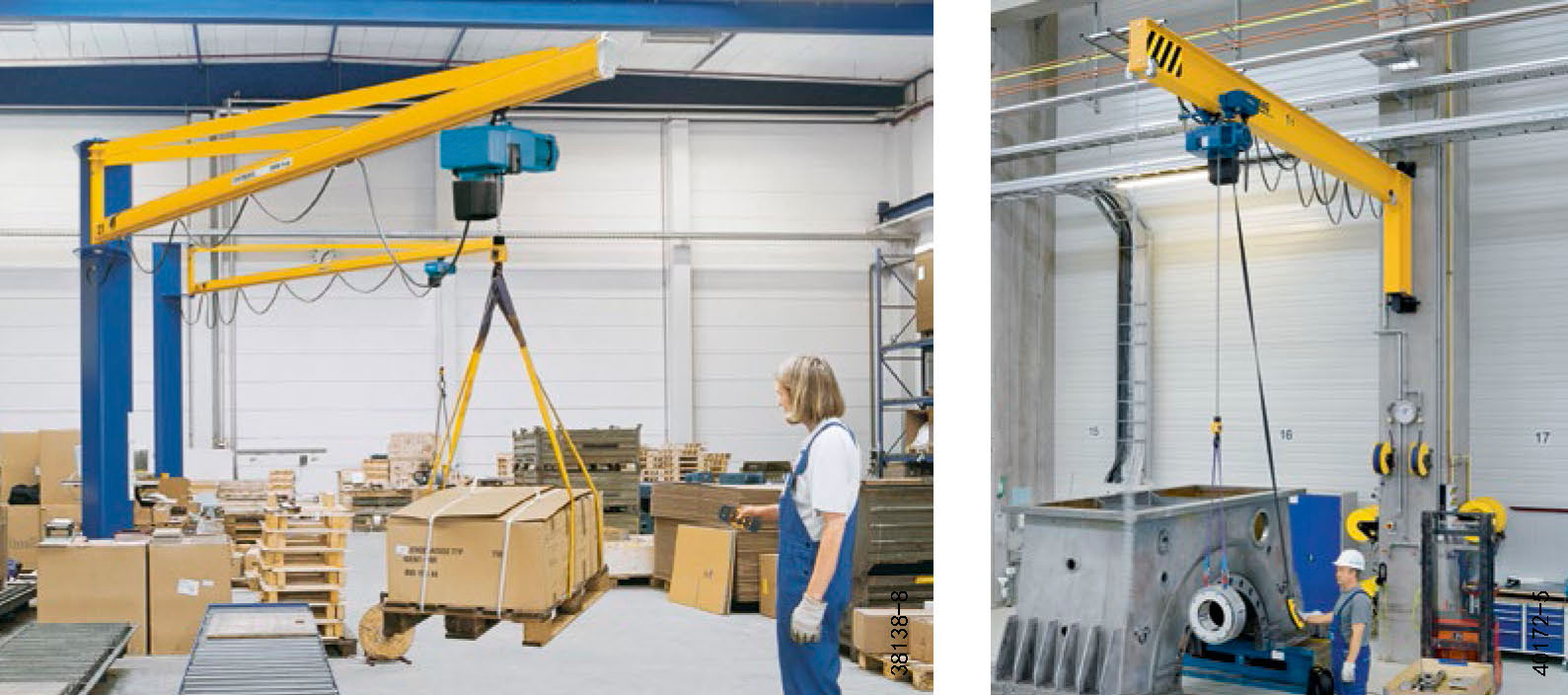

The jib crane connects the electric hoist installed on the mechanical arm to the clamp through a flexible cable, and realizes the lifting and lowering of goods through the lifting and movement of auxiliary lifting equipment.

This equipment is used in conjunction with various non-standard fixtures to realize workpiece handling, palletizing, loading and unloading. It reduces operator fatigue, maximizes productivity, and ensures worker safety. It has a wide range of applications and is especially suitable for modern production lines.

The jib crane consists of three parts: a column and a cantilever, an auxiliary hoist and a non-standard clamp. Auxiliary lifting hoists include electric hoists, smart hoists and pneumatic air balancers.

The lifting Device for The Manipulator

The Jib Crane is comprised of three components: a column and cantilever arm, electric hoist, and a non-standard fixture.

Electric hoist is the most cost-effective option for most applications. The model and specifications will be designed based on the characteristics of the load.

Electric Hoist for Jib Crane

Electric hoists are commonly mounted on jib cranes, such as cantilever, gantry, and truss cranes. They are known for their affordability, ease of use, and low maintenance requirements. These hoists are frequently utilized in factories, warehouses, and similar environments. There are two types of electric hoists based on the lifting cable material: wire rope hoists and chain hoists. Additionally, electric hoists come in two speed options: single-speed lifting and two-speed lifting.

Electric Hoist Models for Reference

Here we put some of the electric hoist models that we used mostly for our programs for your reference.

Electric hoist

NAME | BMS125 | BMS250 | BMS500 | BMS1000 | BMS2000 |

Maximum load(Kg) | 125 | 250 | 500 | 1000 | 2000 |

Lifting speed (m/ min) | 8/2 | 8/2 | 8/2 | 4/1 | 4/1 |

Motor power(Kw) | 0.4/0.1 | 0.4/0.1 | 0.4/0.1 | 0.75/0.2 | 1.5/0.37 |

Lifting Medium | Chain | ||||

Power supply | 220-460V | ||||

INSTALLATION WAY

1.Cantilever crane

2.Folding arm crane

3.Movable base cantilever crane

4.Truss crane

Product Operation Guide

The jib crane consists of three parts: column and cantilever, auxiliary lifting equipment and non-standard clamps. The auxiliary lifting equipment installed on the robotic arm is connected to the clamp through a stainless steel flexible cable to realize the lifting function.

The lifting hoist is used with various non-standard clamps. According to the needs of past customers, equipment can be designed to perform corresponding work. By controlling the corresponding buttons, materials can be adsorbed, transferred, lifted, turned over, released, etc.

Electric hoists are widely used in the automotive industry (including engines, gearboxes, new energy battery assembly, etc.), finishing, machinery manufacturing, processing, highly repetitive handling work in the energy industry, product parts assembly, warehouse loading and unloading, product packaging, etc.

WORKING SCENARIO

content is empty!