- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

SLJ-RAM

Product Description

| Condition | New | Application | Use for handling boxes, blocks, cylinder, machinery parts | |

| Type | Manipulator with clamping claws/fixture | Capacity | 50kg-500kg, Customized | |

| Up and Down Stroke | 0-2000mm, Customized | Working Radius | 2500-3000mm, Customized | |

| Max Height | 3500mm, Customized | Basic Design | Clamping, Lifting, Rotating | |

| Installation Form | Customized | Specification | Customized | |

| Transport Package | Wood Box | Origin | China | |

| Trademark | Escott, or customized | Production Capacity | 100 pcs/Month |

The industry manipulator is a set of assisted handling equipment designed based on dynamics and ergonomics, and its operation mode is through manual button operation, by the gripping of the fixture tool to achieve the transfer action of the object.

In this process, irregular objects, heavy objects, and special objects have achieved efficient transfer, saving and protecting manpower loss, and it’s been more and more widely used in the industrial production process.

Industrial manipulators can easily handle any product weighing up to 500Kg using only compressed air.

Thanks to the nearly "weightless" and "zero-gravity balance" operating methods, operators can safely and easily grab parts from any direction and angle and achieve accurate placement.

This design employs clamping claws that are customized and automated according to the object's attributes, including its form, mass, and exterior. It provides diverse clamping techniques, yet the fundamental principle remains consistent - gripping the load externally and subsequently conveying it along the assembly line. The loads must possess a standardized shape.

They should be of a suitable dimension to ensure the claws can firmly grasp them externally.The load's weight usually varies between 50 and 300kg.

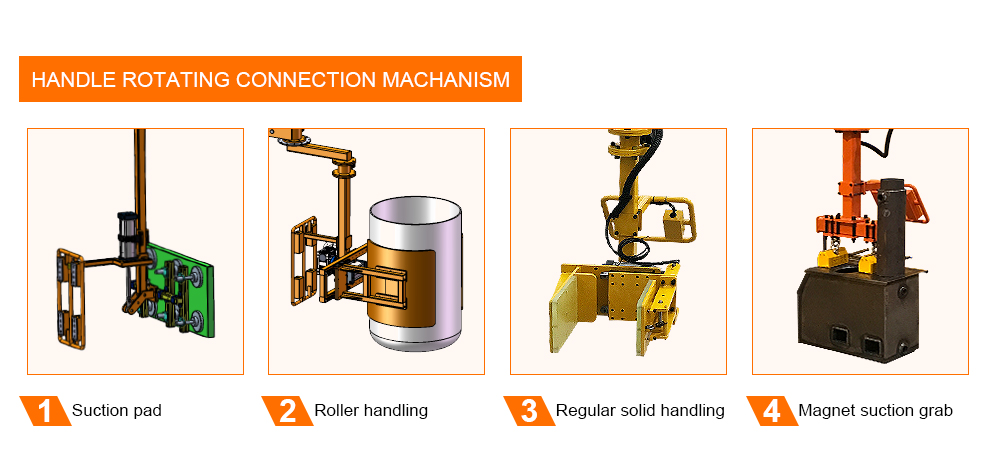

Some other Fixture Tooling Types for your reference

Each intallation has its own advantage and it is totally base on the project need, and the working condition of the customers' workshop.

1.Fixed Column: most choice

2.Movable Column

3.Fixed Overhead (Wall installation)

4. Running Overhead (by Sliding trolley)

Industrial manipulators imitate the movements of human hands to grab and carry goods, which can effectively reduce manpower and reduce labor costs.

Manipulators are widely used in machinery manufacturing, casting industry, chemical and pharmaceutical industry, auto parts industry, automobile assembly, glass processing, packaging, papermaking, and printing industries. Manipulators can handle workpieces and products of various shapes and weights. For example: bags, cartons, chemical drums, oil drums, plastic rolls, glass, plates, air conditioners, condensers, compressors, metal castings, molds, sand cores, car tires, front walls, skylights, instrument panels, cylinder heads, etc. . Each manipulator's gripper is designed and manufactured specifically to the customer's specifications and is used to handle a wide range of products of varying weights and sizes.

We are a leading manufacturer specializing in innovative and reliable material handling solutions. With over 10 years of industry experience, our skilled team of engineers and technicians has developed a diverse range of handling machines,Our Product including:

- Lifting Equipment

- Pneumatic Rigid Arm Manipulators

- Vacuum Lifters

- JIB Cranes

- Overhead Cranes

- Intelligent Hoists

- Pneumatic Balance Cranes

- Customized Solutions for specific industries

Our commitment to quality and customer satisfaction has made us a trusted name in the industry. We prioritize building long-term partnerships with our clients by offering exceptional pre-sales and after-sales services. This includes comprehensive training, maintenance support, and prompt technical assistance, ensuring our customers maximize the value of our products and achieve their operational goals.

If you’re looking for a reliable partner in material handling, we invite you to connect with us.

Our professional team will work closely with you to deeply understand your needs, industry characteristics and application scenarios to ensure that the product design meets your expectations.

2. Customized design

According to your specifications and requirements, we provide flexible design solutions covering size, function and material selection to ensure the best performance of the final product.

3. High-quality production

We use advanced production technology and strict quality control to ensure that each customized product has excellent quality and reliability.

4. Fast delivery

We optimize the production process to quickly respond to customer needs and ensure that customized products are delivered on time within the agreed time.

5. After-sales support

We provide comprehensive technical support and maintenance services to ensure that the system continues to operate efficiently, and customers can get professional after-sales service and technical guidance at any time.

Q:Are you a manufacture or trading company?

A:We are the manufacturer, has more than ten years of production experience

Q: How long is your delivery time?

A: It is Usually 20 days after confirming the technical sheet and drawings.

Q: What is your price?

A: The price depends on your requirements for the equipment. Accordingto the model, the price is relatively different.

Q: What is the condition of your machine?

A: Brand new, can be customized.

Q:What is the guarantee of after-sales service?

A:Replacement parts within one year, lifelong technical guidance

Q:Mode of transportation?

A: You can choose sea, air, rail transportation (FOB, CIF, CFR, EXW, etc.)

Q:What problems can the roll handling manipulator solve?

A:1.Perform dangerous or heavy operations in place of humans

2.Improve production efficiency and quality

3.Reduce labor costs and so on