- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

SLJ-100D

Product Description

Basic Info.

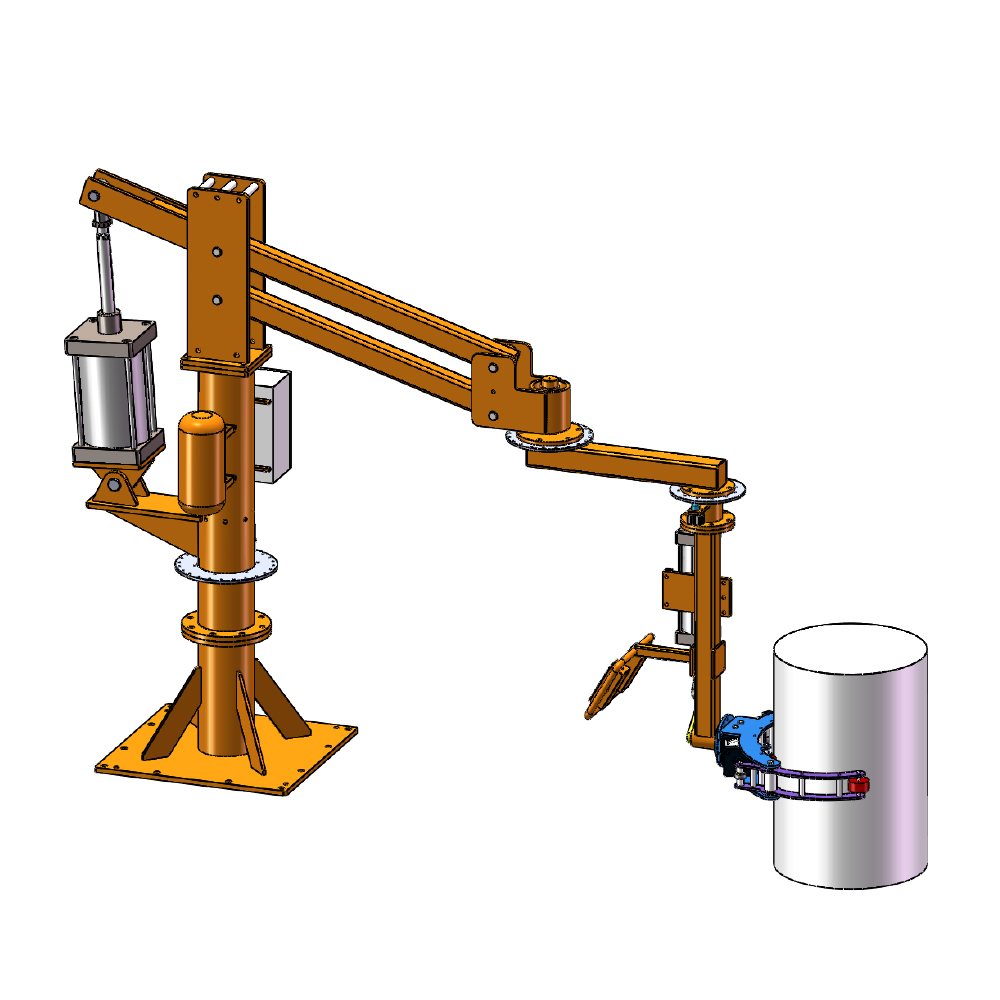

| Condition | New | Application | Use for handling Silicon rods, rod-like objects,cylinders,rolls | |

| Type | Manipulator with Clamping Fixture | Capacity | 100kg, Customized | |

| Up and Down Stroke | 0-2000mm, Customized | Working Radius | 2500-3000mm, Customized | |

| Max Height | 3500mm, Customized | Basic Design | Clamping, Lifting, Rotating | |

| Installation Form | Customized | Specification | Customized | |

| Transport Package | Wood Box | Origin | China | |

| Trademark | Escott, or customized | Production Capacity | 100 pcs/Month |

General Introduction

The manipulator is operated using buttons and uses specialized tools to grip and move objects.

The manipulator is commonly used in the following situations:

1.When an object is too heavy or large to be moved manually.

2.When it is difficult to find the right angle and position for manually relocating an object.

3.When manual object relocation can result in significant waste.

4.When manual object relocation can lead to a significant reduction in the workforce.

To overcome these challenges,manipulators are designed to efficiently move irregular, heavy and unique items, thus protecting the workforce. Therefore,manipulators are becoming more and more popular in various industrial production processes.

Industrial manipulators can easily handle any product weighing up to 500Kg using only compressed air.

The operating objects involve box palletizing, material dumping, reel up and down line, bag handling, metal workpiece handling, silicon rod transplanting, automotive parts and assembly, and so on.The industrial manipulator can perfectly balance the load weight, thanks to the operation mode of "weightlessness" and "zero gravity balance".

Design Sketch for different kind of loads

|  |

|  |

Working Object Description

This manipulator uses its mechanical gripper to pick up the silicon rod from one position, rotate it to a suitable posture, and place it in another position. After completing a processing step, the silicon is sucked by the suction cup and placed in the appropriate position. According to the above working principle, this equipment can also be expanded to handle other rod-shaped objects, cylinders, and rolls.

Product Operation Guide

1. Operation platform: equipped with load control system, material grasping, transfer and extraction can be realized through the control button; The mechanical gripper must ensure that the workpiece can be grasped, moved and discharged smoothly.

2. Safety protection: equipped with safety misoperation protection device (the work is not in place, the workpiece can not be unloaded), supporting safety control system (the manipulator will not rise and fall rapidly because of misoperation), brake device.

content is empty!