- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

SLJ-150C

Product Description

Basic Info.

| Condition | New | Application | Use for handling Coton Bale in Textile industry | |

| Type | Manipulator with Clamping Fixture | Capacity | 150kg, Customized | |

| Up and Down Stroke | 0-2000mm, Customized | Working Radius | 2500-3000mm, Customized | |

| Max Height | 3500mm, Customized | Basic Design | Clamping, Lifting, Rotating | |

| Installation Form | Customized | Specification | Customized | |

| Transport Package | Wood Box | Origin | China | |

| Trademark | Escott, or customized | Production Capacity | 100 pcs/Month |

General Introduction

The industry manipulator is a type of assistance equipment designed using principles of dynamics and ergonomics. It is operated manually through buttons, using fixture tooling to transfer objects.

We introduce the manipulator as a helpful tool for handling. It efficiently transfers irregular, heavy, and special objects, thereby saving and protecting manpower. As a result, it is increasingly being used in industrial production processes.

Industrial manipulators imitate the movements of human hands to grab and carry goods, which can effectively reduce manpower and reduce labor costs.

Our solutions are all non-standard designs, fully meeting the different needs of each customer and tailor-made. The equipment's height, reach, lifting stroke, load capacity, appearance, color, and installation form are all customized according to the site space and needs. At the same time, the clamping system will be fully non-standardized and customized to be most suitable for workpiece handling.

Design Sketch for different kind of loads

|  |

|  |

Description of Working Object

The customer of this equipment is a famous Japanese diaper manufacturer. Industrial robots are used to move large cotton bales. We installed a customized pneumatic clamp on the robot arm, and controlled the robot arm and its clamp through the buttons on the panel to transport the cotton bales on the assembly line. Our robots are purchased by a large number of domestic companies and also exported overseas.

We customize our products to fully meet each customer's refined needs. The height, arm span, lifting stroke, load capacity, appearance color, installation form, etc. of the equipment are all customized according to the on-site space and needs. The clamping system will be completely customized to suit the workpiece handling needs.

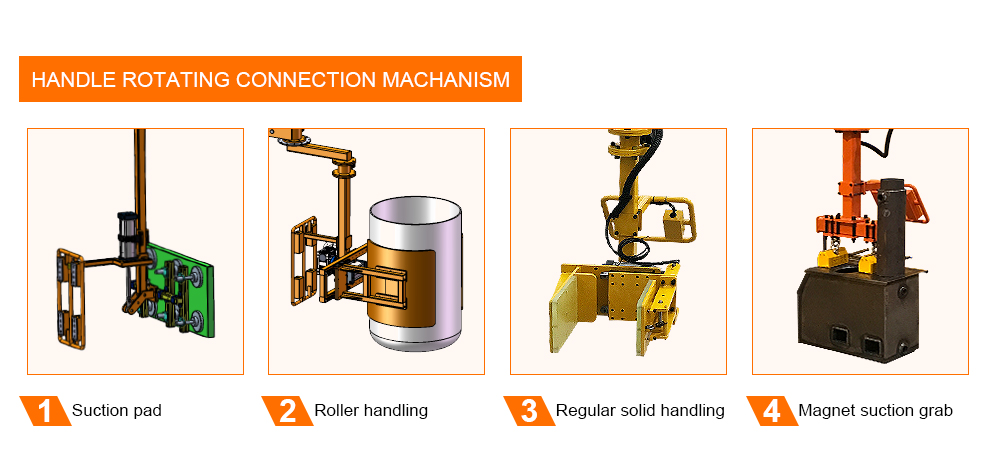

Some other Fixture Tooling Types for your reference

Installation Way

Each intallation has its own advantage and it is totally base on the project need, and the working condition of the customers' workshop.

1.Fixed Column: most choice

2.Movable Column

3.Fixed Overhead System ( or on-wall installation)

4. Overhead Running system (by Sliding trolley)

Product Operation Guide

1. Basic design: The equipment can be lifted and rotated freely in 360 degrees, which can complete the three-dimensional space load shifting action during the grasping, handling, lifting and docking of the workpiece, and can meet the requirements of material extraction.

2. Operation platform: equipped with load control system, material grasping, transfer and extraction can be realized through the control button; The mechanical gripper must ensure that the workpiece can be grasped, moved and discharged smoothly.

3. Safety protection: equipped with safety misoperation protection device (the work is not in place, the workpiece can not be unloaded), supporting safety control system (the manipulator will not rise and fall rapidly because of misoperation), brake device.

content is empty!