- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

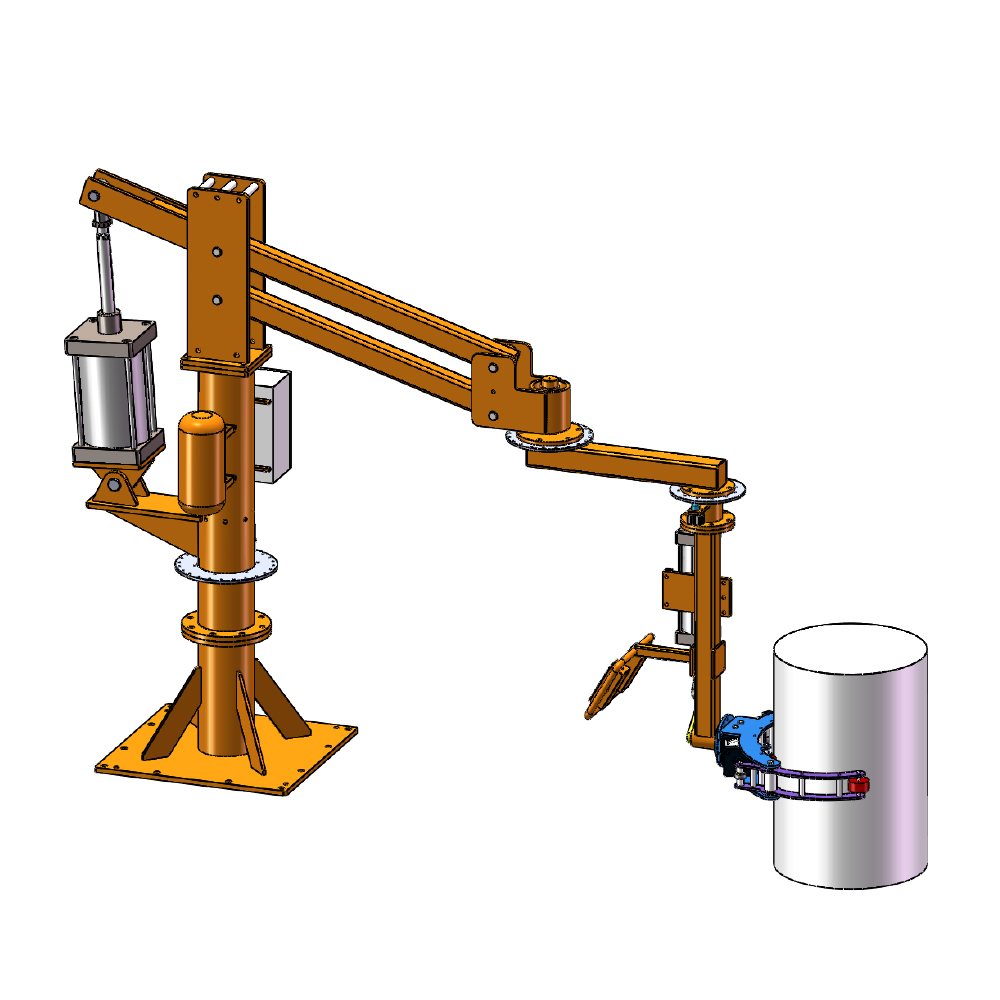

SLJ-200A

Product Description

Basic Info.

| Condition | New | Application | Use for handling Metal column,reel,roll | |

| Type | Manipulator with Clamping Fixture | Capacity | 100kg-300kg, Customized | |

| Up and Down Stroke | 0-2000mm, Customized | Working Radius | 2500-3000mm, Customized | |

| Max Height | 3500mm, Customized | Basic Design | Clamping, Lifting, Rotating | |

| Installation Form | Customized | Specification | Customized | |

| Transport Package | Wood Box | Origin | China | |

| Trademark | Escott, or customized | Production Capacity | 100 pcs/Month |

General Introduction

The industry manipulator is a tool that assists in handling items. It is designed based on the principles of movement and comfort. The manipulator is operated using buttons and uses specialized tools to grip and move objects.

The manipulator is often used in the following situations:

1.When an object is too heavy or large to be moved manually.

2.When it is difficult to find the right angle and position for manually relocating an object.

3.When manual object relocation can result in a lot of waste.

4.When manual object relocation can lead to a significant decrease in workforce.

To overcome these challenges, the manipulator is a valuable tool for handling objects. It allows for efficient movement of irregular, heavy, and unique items, thereby saving and protecting the workforce. As a result, the manipulator is becoming increasingly popular in various industrial production processes.

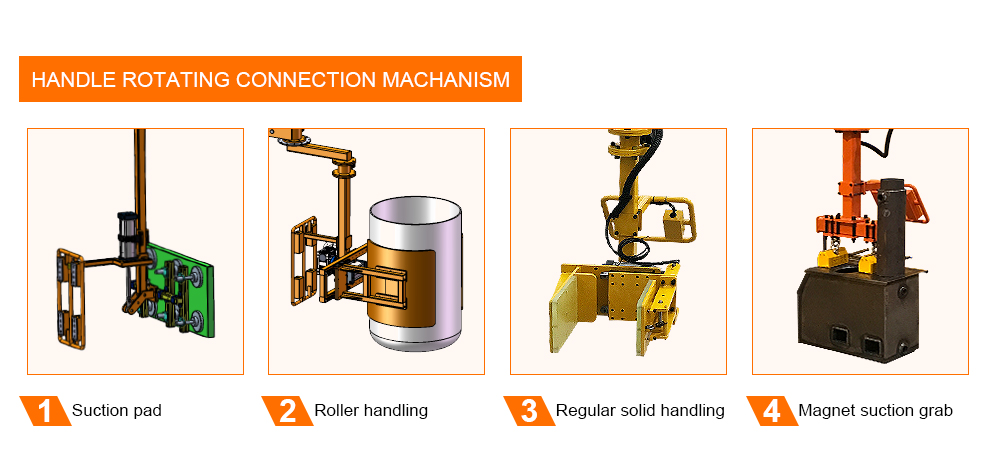

Design Sketch for different kind of loads:

|  |

|  |

Working Object Description

The manipulator operates by utilizing its mechanical gripper to lift the Metal column from a specific spot, rotate it to an appropriate position, and then relocate it to another spot. By following this working principle, the device can also be adapted to handle other objects with a column-like shape, such as reel or roll. This particular product finds extensive applications in various industries, including machinery manufacturing and casting.

During the entire process of equipment selection and design, ensuring safe production is always our priority. At the same time, the efficiency of handling and ergonomics are also our key considerations. The equipment strives to reduce the operator's operating force on the workpiece to Within 3-5Kg, through better control of the lifting operation, it is possible to improve operational safety, reduce the occurrence of accidents, and greatly avoid the occurrence of operator strain injuries.

Some other Fixture Tooling Types for your reference

content is empty!