- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

SLJ-80-R-FT

Escott

Product Description

Basic Info.

| Condition | New | Application | Use for handling regular blocks like boxes, cartons, blocks | |

| Type | Manipulator with Clamping Fixture | Capacity | 80kg-500kg, Customized | |

| Up and Down Stroke | 0-2000mm, Customized | Working Radius | 2500-3000mm, Customized | |

| Max Height | 3500mm, Customized | Basic Design | Clamping, Lifting, Rotating | |

| Installation Form | Customized | Specification | Customized | |

| Transport Package | Wood Box | Origin | China | |

| Trademark | Escott, or customized | Production Capacity | 100 pcs/Month |

General Introduction

Our team has more than 10 years of experience in assisting manipulators and has always been committed to solving the problem of handling heavy objects on the production line.

The industry manipulator is a set of assisted handling equipment designed based on dynamics and ergonomics.It is capable of lifting various products weighing up to 500 kg.

General application scenarios mainly include:

1. The target object is too heavy or too large to be transported manually.

2. The transmission angle and position of the target object are difficult to achieve manually

3. Manual transfer of target objects can easily cause high losses

4. Target objects can easily cause large human losses.

Based on the above situation, we introduced the manipulator as an auxiliary handling tool to solve the problem perfectly. The operation objects involve everything from box palletizing, material dumping, reel loading and unloading, packaging bag handling, metal workpiece handling, silicon rod transplanting, automobile parts and assembly, etc. It’s been more and more widely used in the industrial production process.

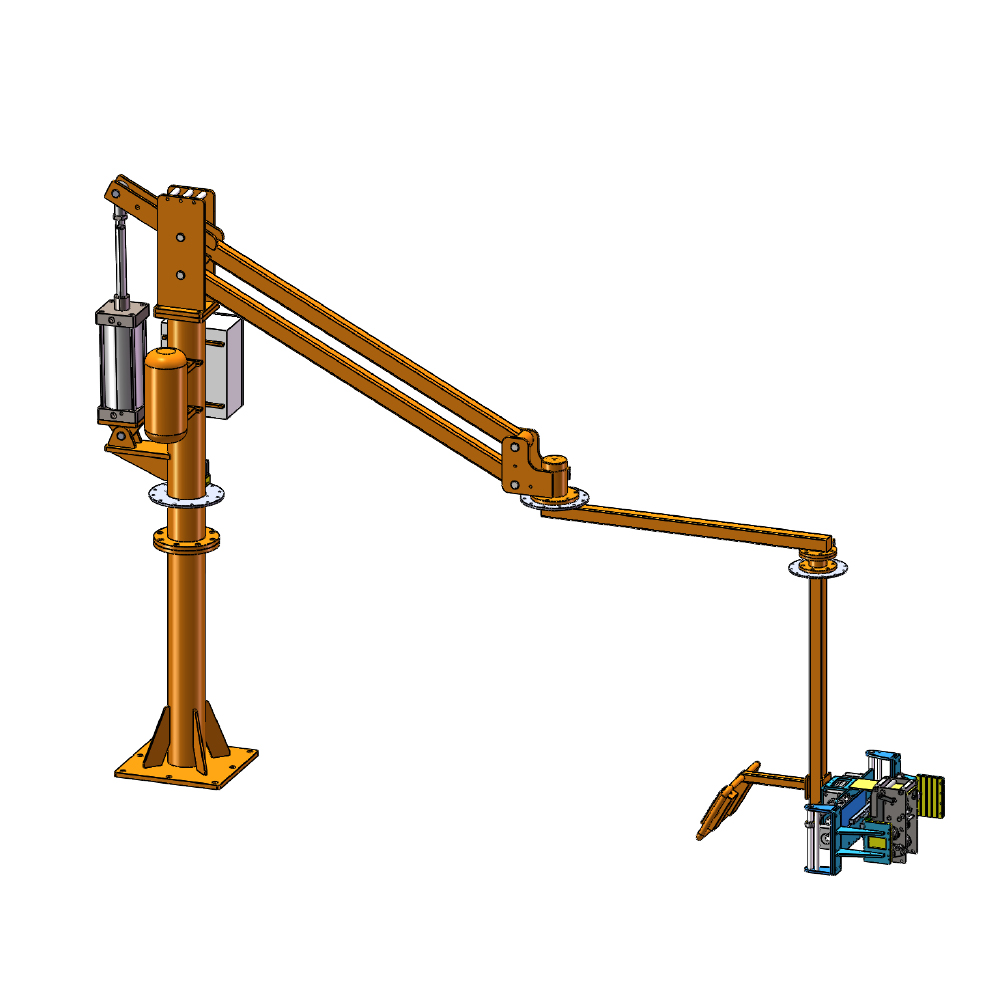

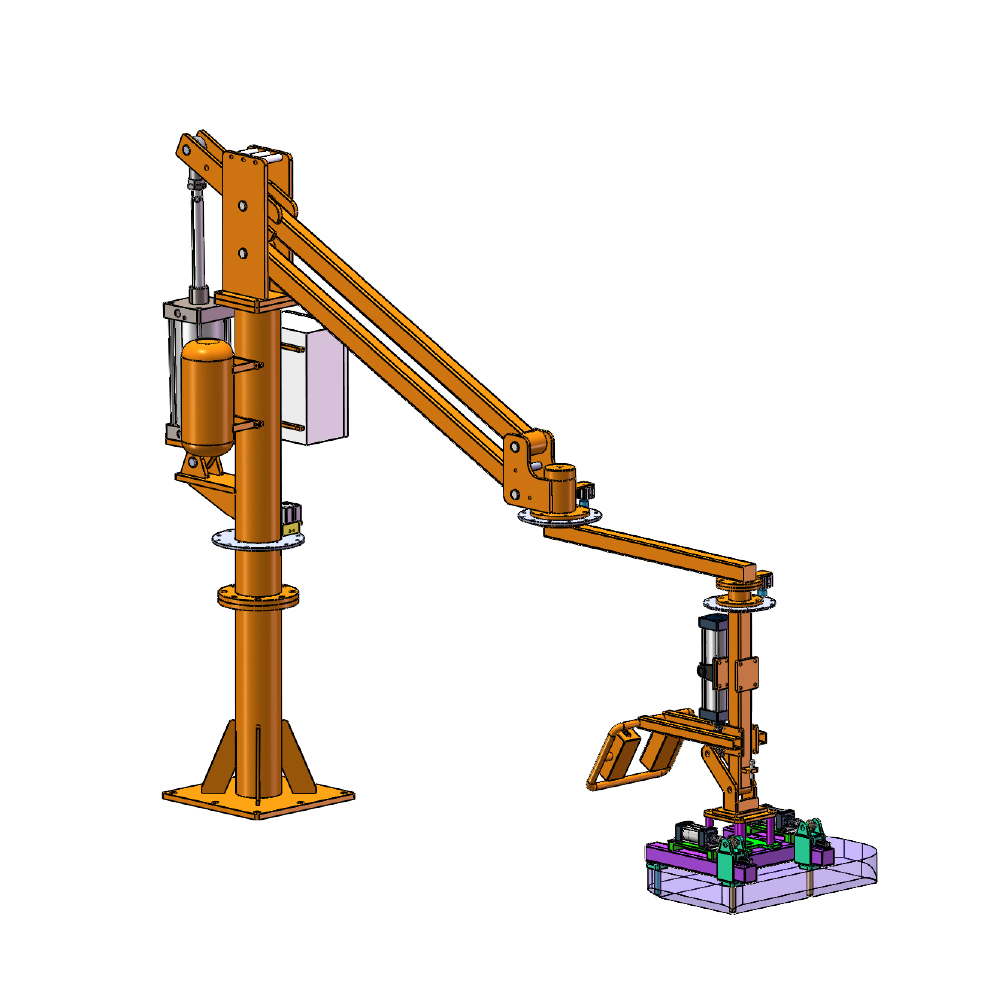

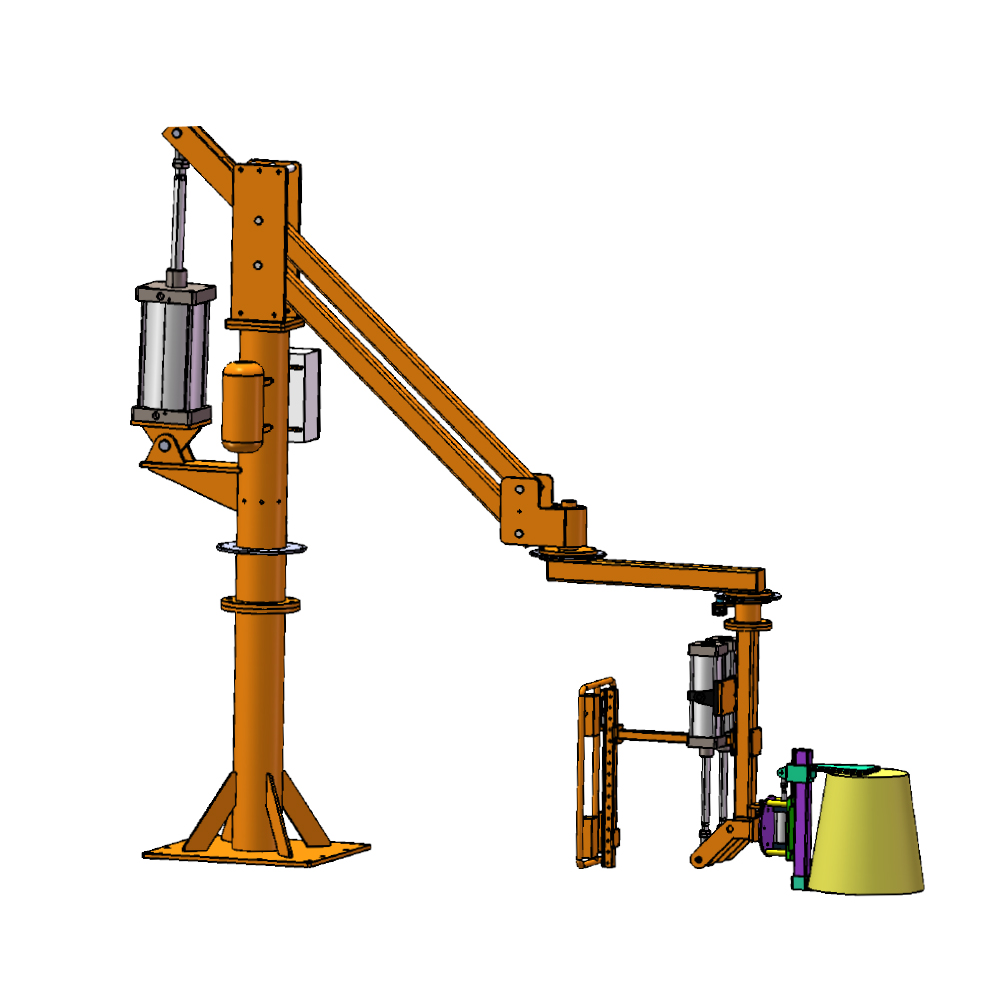

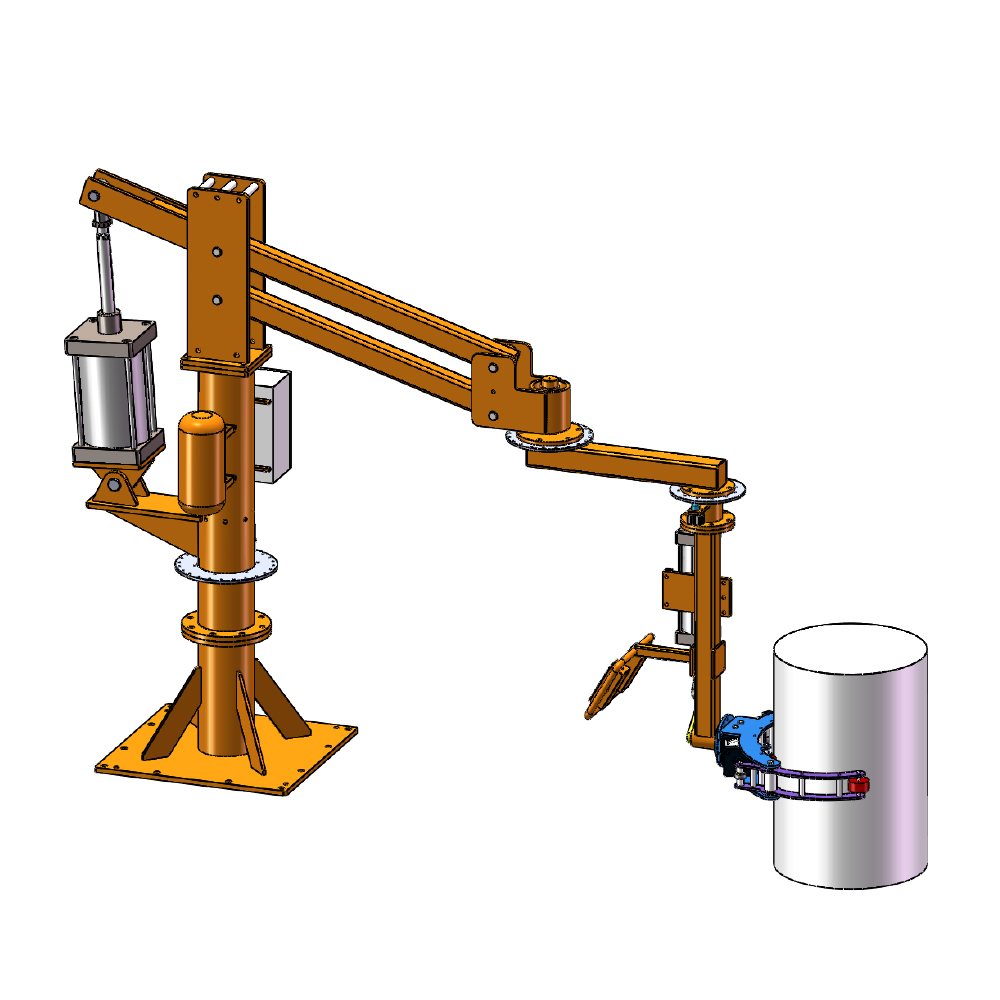

Design Sketch for different kind of loads:

|  |

|  |

Working Object Description:

This kind of design used clamping claws--shape and machnism designed base on the object shape, weight, surface etc, and it has different clamping ways, but the working method is similar like clamping from the outside of the load, then move and transfer in production line. Mostly the shape contains cylinder, cone, rectangular etc. Screens, boards, hard blocks, rolls and other types. The requirement for the loads would be like :

1. Regular shape

2. Proper size to make sure the claws can fix it from outside

2. Weight mostly from 50 to 300kg

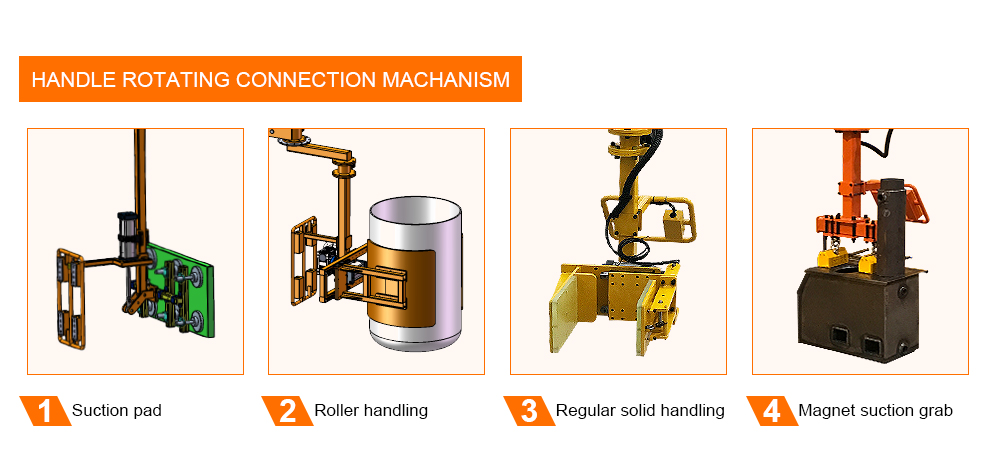

Some other Fixture Tooling Types for your reference

Installation Way

Each intallation has its own advantage and it is totally base on the project need, and the working condition of the customers' workshop.

1.Fixed Column: most choice

2.Movable Column

3.Fixed Overhead (Wall installation)

4. Running Overhead (by Sliding trolley)

Product Operate Guide

1. Basic design: The equipment can be lifted and rotated freely in 360 degrees, which can complete the three-dimensional space load shifting action during the grasping, handling, lifting and docking of the workpiece, and can meet the requirements of material extraction.

2. Operation platform: equipped with load control system, material grasping, transfer and extraction can be realized through the control button; The mechanical gripper must ensure that the workpiece can be grasped, moved and discharged smoothly.

3. Safety protection: equipped with safety misoperation protection device (the work is not in place, the workpiece can not be unloaded), supporting safety control system (the manipulator will not rise and fall rapidly because of misoperation), brake device.

Application Scenario

content is empty!