- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

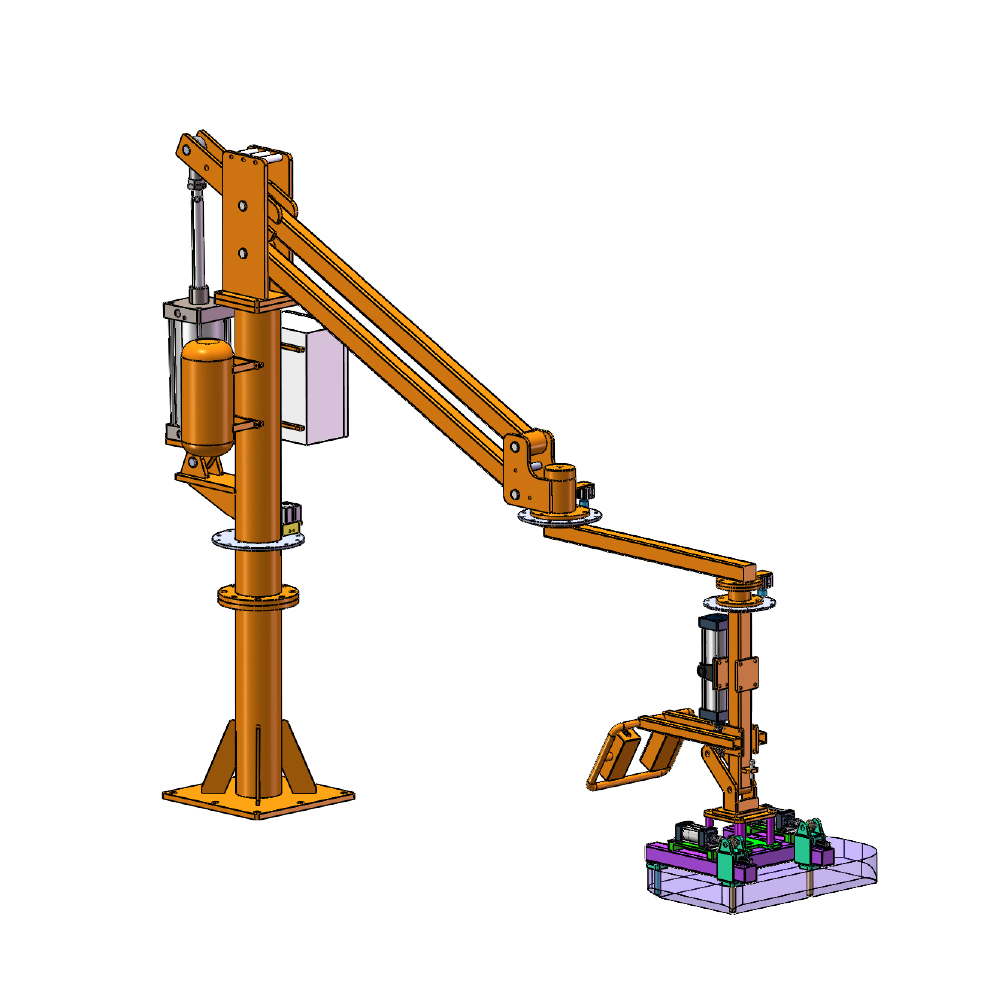

SLJ-100B

Product Description

Basic Info.

| Condition | New | Application | Use for handling Metal profiles, and other regular shape loads | |

| Type | Manipulator with Suction Cups Fixture | Capacity | 300kg, Customized | |

| Up and Down Stroke | 0-1600mm, Customized | Working Radius | 2500-3000mm, Customized | |

| Max Height | 3500mm, Customized | Basic Design | Clamping, Lifting, Rotating | |

| Installation Form | Ground Installation, Customized | Specification | Customized | |

| Transport Package | Wood Box | Origin | China | |

| Trademark | Escott, or customized | Production Capacity | 100 pcs/Month |

General Introduction

The industry manipulator is a set of equipment that assists with handling tasks. It is designed with a focus on dynamics and ergonomics. The manipulator is operated using manual buttons, and it uses fixture tooling to grip and transfer objects.

The main scenarios where the manipulator is used are:

1.When the object is too heavy or large for manual handling.

2.When it is difficult to achieve the desired angle and position for transferring the object manually.

3.When manual transfer of the object can result in high loss.

4.When manual transfer of the object can result in significant loss of manpower.

To address these situations, we have introduced the manipulator as a tool for assisting with handling tasks. This tool has proven to be effective in transferring irregular, heavy, and special objects efficiently. It helps to save and protect manpower, and its usage is becoming increasingly common in industrial production processes.

Design Sketch for different kind of loads:

|  |

|  |

Working Object Description

This type of design utilizes suction pads as the fixing tool, and it is commonly used in metal profiles, boards, doors, and glass during production. We encounter various application scenarios, but in most cases, the objects being worked on should have a flat and smooth surface for the suction to function properly.

1.The surface should be even and without any irregularities.

2.The material of the object should possess sufficient strength.

3.The weight typically ranges from 50 to 300kg, and the type and number of suction pads will be determined based on the workload.

Installation Way: installation way bases on the condition of the workshop.

1.Fixed Column

2.Movable Column

3.Fixed Overhead (Wall installation)

4. Running Overhead (by Sliding trolley)

Product Advantage

Industrial manipulators are equipment that assist in handling on production lines. The equipment has the characteristics of simple operation, safety, reliability and convenient maintenance. Quick processing of workpieces can be achieved with simple button operations. It is currently the most advanced industrial robot. It is an ideal handling equipment for modern production lines, warehouses, etc.

It has high stability and simple operation. Adopting full pneumatic control, you only need to operate the control switch to complete the workpiece handling process. High efficiency and short transportation cycle. After transportation starts, the operator can control the movement of the workpiece in space with very little force and can stop it at any position. The shipping process is simple, fast and consistent.

Application Scenario

content is empty!