- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

SLJ-150B

Product Description

Basic Info.

| Condition | New | Application | Use for handling Roll, Blocks, Board,Coton Bale | |

| Type | Manipulator with Clamping Fixture | Capacity | 100kg-500kg, Customized | |

| Up and Down Stroke | 0-2000mm, Customized | Working Radius | 2500-3000mm, Customized | |

| Max Height | 3500mm, Customized | Basic Design | Clamping, Lifting, Rotating | |

| Installation Form | Customized | Specification | Customized | |

| Transport Package | Wood Box | Origin | China | |

| Trademark | Escott, or customized | Production Capacity | 100 pcs/Month |

General Introduction

Industrial manipulators are ergonomic and can handle any product safely and efficiently. Capable of lifting various products weighing up to 500 kg. The manipulator mimics the action of the human hand to grasp and carry goods, which can effectively reduce manpower and reduce labor costs.

The main situations where the manipulator is commonly utilized are as follows:

1.When the target object is too burdensome or bulky to be handled manually.

2.When it is challenging to achieve the desired transfer angle and position of the target object manually.

3.When manually transferring the target object can lead to significant loss.

4.When manually transferring the target object can result in a considerable loss of manpower.

As a result, we introduce the manipulators as a beneficial tool for handling.They are increasingly being integrated into various industrial production processes.

Product Advantage

The industry manipulator is used in the production line to help the handling equipment, the equipment is simple to operate, safe and reliable, easy maintenance and other significant features, only a simple button operation can achieve the rapid handling of the workpiece, is the most ideal handling equipment for modern production lines, warehouses and so on.

This kind of machine has the characteristics of light structure, easy disassembly and assembly, and wide use. High stability, simple operation. With full pneumatic control, only one control switch can be operated to complete the workpiece handling process. High efficiency, short handling cycle. After the handling begins, the operator can control the movement of the workpiece in the space with a small force, and can stop at any position, and the handling process is easy, fast and coherent.

Working Object Description

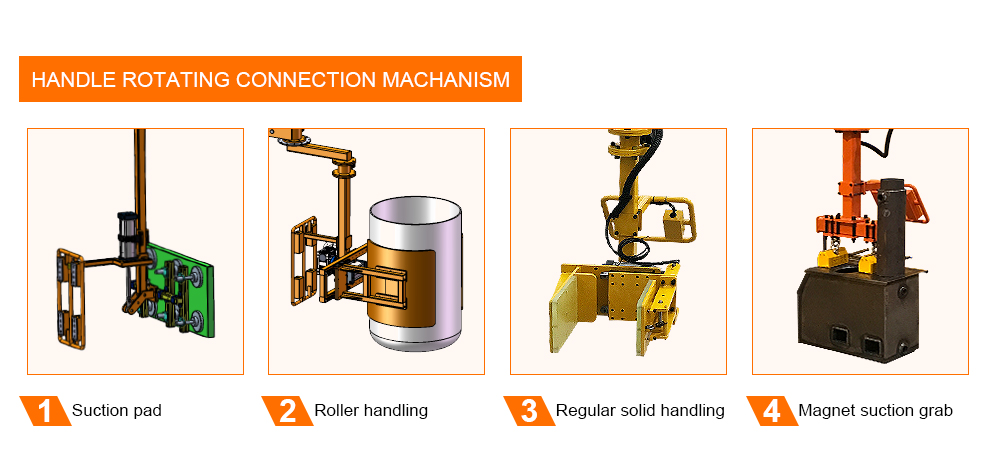

This type of design utilizes clamping claws that are shaped and mechanized based on the characteristics of the object, such as its shape, weight, and surface. It offers various clamping methods, but the overall working principle remains the same - clamping the load from the outside and then transferring it along the production line.

Pneumatic assisted manipulator combines with non-standard customized pure pneumatic fixture to achieve clamping, rotation, flipping, load shifting and other operations.

Some other Fixture Tooling Types for your reference

Installation Way

Each intallation has its own advantage and it is totally base on the project need, and the working condition of the customers' workshop.

1.Fixed Column: most choice

2.Movable Column

3.Fixed Overhead (Wall installation)

4. Running Overhead (by Sliding trolley)

Product Operate Guide

1. Operation platform: equipped with load control system, material grasping, transfer and extraction can be realized through the control button; The mechanical gripper must ensure that the workpiece can be grasped, moved and discharged smoothly.

2. Safety protection: equipped with safety misoperation protection device (the work is not in place, the workpiece can not be unloaded), supporting safety control system (the manipulator will not rise and fall rapidly because of misoperation), brake device.

Application Scenario

content is empty!