- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

EST120

Product Description

Basic Info.

| Condition | New | Application | Use for handling bags,sacks | |

| Type | Vacuum lifter | Capacity | 15-300kg, Customized | |

| Up and Down Stroke | 100-1800mm, Customized | Working Radius | 3000mm, Customized | |

| Max Height | 3650mm, Customized | Basic Design | Sucking, Lifting | |

| Installation Form | Ground Installation, Customized | Specification | Customized | |

| Transport Package | Wood Box | Origin | China | |

| Trademark | Escott, or customized | Production Capacity | 100 pcs/Month |

General Introduction

It uses the principle of vacuum suction and lifting to suck and transport various workpieces. The suction, lifting, lowering and releasing of workpieces are all achieved by controlling a light and flexible control rod. When the suction cup is placed on an object, a lower pressure is created in the lifting unit, and the difference in pressure causes the tube to shrink vertically. The vacuum keeps objects attached to the suction pad and reduces the weight of the objects being moved, whereby the force used by the mover is almost zero.

Vacuum tube lifters handle a variety of objects regardless of their shape. Widely used in food, chemical, pharmaceutical and other industries.

The operation of the vacuum tube hoist is very simple. Depending on the material, it can be operated with one hand or both hands. The suction and release can be completed with one hand, which greatly saves the labor cost in the workshop.

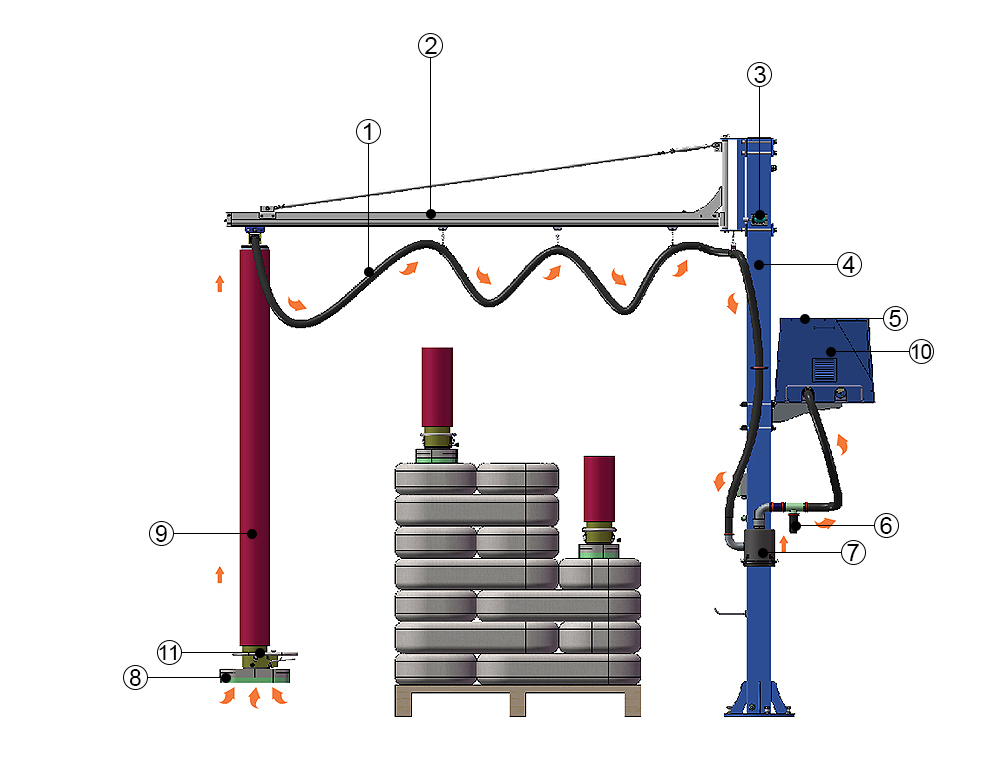

Parts and Structure

1. Air Hose

2. Rail

3. Rail Limit

4. Column

5. Silence Box (optional)

6. Pressure Release Valve

7. Filter

8. Suction Foot

9. Lifing Unit

10. Vacuum Pump

11. Control Handle

Models for Reference

Model | EST100 | EST120 | EST140 | EST160 | EST180 | EST200 | EST230 | EST250 | EST300 |

Suction Power | 30 | 50 | 60 | 70 | 90 | 120 | 140 | 200 | 300 |

Air Hose Length | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 |

Air Hose Diameter | 100 | 120 | 140 | 160 | 180 | 200 | 230 | 250 | 300 |

Lifting Speed | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s |

Lifting Height(mm) | 1800 | 1800 | 1800 | 1800 | 1800 | 1700 | 1700 | 1500 | 1500 |

Vacuum pump | 2.2Kw | 2.2Kw | 2.2Kw | 3Kw | 3Kw | 3Kw | 3Kw | 3Kw | 3Kw |

Working Object Description

Packaging bag handling is the most common application of vacuum lifters. It is mainly used for sucking and handling sugar bags, salt bags, milk powder bags, and pharmaceutical bags in the food and pharmaceutical industry, as well as various packaging bags in the chemical industry.

Common bags include woven bags, PE bags, paper bags, etc. The material needs to be strong enough to be dense and airtight on the surface, or breathable on the surface but have an airtight lining on the inside. Our suction cup seal is a soft sponge material that will not cause damage to the bag.

Product Operate Guide

1. Lifting: Use your fingers to pull the control valve stem upward, the negative pressure of the vacuum system increases, the lifting air pipe contracts, and the workpiece rises;

2. Lowering: Use your fingers to control the valve stem downward, the negative pressure of the vacuum system decreases, the lifting air pipe extends, and the workpiece descends;

3. Releasing: Pull the control valve stem to the bottom, the negative pressure of the suction cup is zero, there is no suction between the suction cup and the workpiece, and the workpiece is released;

Application Scenario