- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

Vel140-BL-60

Product Description

Basic Info.

| Condition | New | Application | Use for handling Barrel ,Bucket | |

| Type | Vacuum lifter | Capacity | 15-300kg, Customized | |

| Up and Down Stroke | 100-1800mm, Customized | Working Radius | 3000mm, Customized | |

| Max Height | 3650mm, Customized | Basic Design | Sucking, Lifting | |

| Installation Form | Ground Installation, Customized | Specification | Customized | |

| Transport Package | Wood Box | Origin | China | |

| Trademark | Escott, or customized | Production Capacity | 100 pcs/Month |

General Introduction

The Vacuum Lifter System is a type of handling system that utilizes the airflow in a specific direction to create a vacuum power in the air tube, which will result in suction power, to lift the loads.

The vacuum pump is connected to the lifting pipe through a hose. Once the suction cup comes into contact with the item, it will pick it up. The lifting pipe then retracts and the weight of the load is supported by the vacuum power. It can then be moved effortlessly.

This system enables quick, secure, and efficient operations, reducing the need for manual labor.

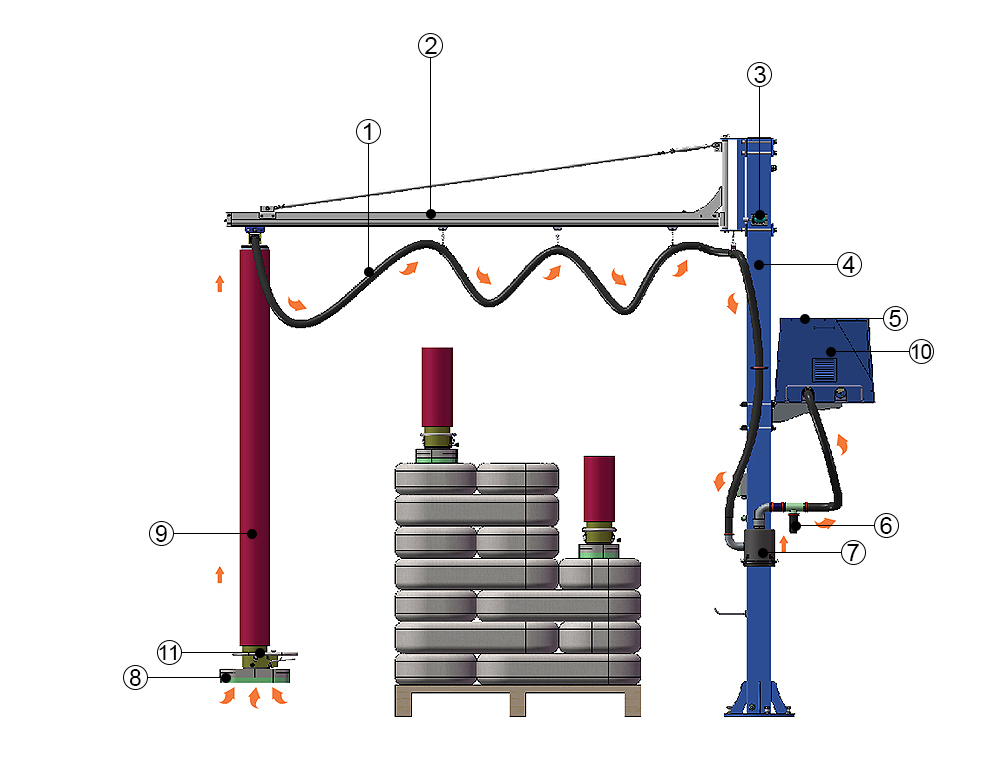

Parts and Structure

1. Air Hose

2. Rail

3. Rail Limit

4. Column

5. Silence Box (optional)

6. Pressure Release Valve

7. Filter

8. Suction Foot

9. Lifing Unit

10. Vacuum Pump

11. Control Handle

Models for Reference

Model | VEL100 | VEL120 | VEL140 | VEL160 | VEL180 | VEL200 | VEL230 | VEL250 | VEL300 |

Suction Power | 30 | 50 | 60 | 70 | 90 | 120 | 140 | 200 | 300 |

Air Hose Length | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 |

Air Hose Diameter | 100 | 120 | 140 | 160 | 180 | 200 | 230 | 250 | 300 |

Lifting Speed | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s |

Lifting Height(mm) | 1800 | 1800 | 1800 | 1800 | 1800 | 1700 | 1700 | 1500 | 1500 |

Vacuum pump | 2.2Kw | 2.2Kw | 2.2Kw | 3Kw | 3Kw | 3Kw | 3Kw | 3Kw | 3Kw |

Working Object Description

We use the suction cup of the vacuum lifter to suck the lid of the barrel for transportation, or for rectangular type, suck on flat surface. The size of the lid is required to match the suction cup, and the middle of the lid is smooth. According to the weight of the barrel, choose the appropriate vacuum lifter. As the weight increases, the lifting tube needs to be thicker and the suction cup size needs to be larger. Therefore, when selecting equipment, not only the weight of the barrel should be paid attention to, but the size of the barrel cover is also very important.

Vacuum energy is stored in the vacuum accumulator, and it can be transferred to the suction cup within one second and sucked instantly; the speed of release can be controlled manually, and no sudden release will cause damage to the workpiece. The suction cup can be detached from the object instantly due to the fast inflation speed. Improve operational efficiency.

Pneumatic operation is basically low noise and has very little impact on the operator and the surrounding environment.

Applicable Industry

Vacuum lifters are mainly used in agriculture, chemical industry, food, medical care, hardware industries, etc. They can be used to transport bags, cartons, barrels or other items, such as transporting rubber, lifting aluminum coils, etc. This kind of vacuum lifter is also suitable for packing and transporting main engines, packing water heaters, etc. The vacuum lifter can be hung on the track and form a perfect whole with the assembly line system.

Application Scenario