- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

EST140

ESCOTT

Product Description

Basic Info.

| Condition | New | Application | Use for handling bags,sacks | |

| Type | Vacuum lifter | Capacity | 15-300kg, Customized | |

| Up and Down Stroke | 100-1800mm, Customized | Working Radius | 3000mm, Customized | |

| Max Height | 3650mm, Customized | Basic Design | Sucking, Lifting | |

| Installation Form | Ground Installation, Customized | Specification | Customized | |

| Transport Package | Wood Box | Origin | China | |

| Trademark | Escott, or customized | Production Capacity | 100 pcs/Month |

General Introduction

The Vacuum tube lifter is a fast, safe and convenient automated equipment. It uses the principle of vacuum adsorption, using a vacuum pump or vacuum blower as a vacuum source to generate vacuum at the suction cup end, thereby firmly sucking up various workpieces. It transports the workpiece to a designated location through a rotatable robotic arm.

Vacuum tube lifters are widely used in agriculture, chemicals, food, healthcare, hardware and other industries, and are suitable for objects of any size and shape, such as bags, boxes, barrels, wooden boards, other boards, metal, glass windows, etc.

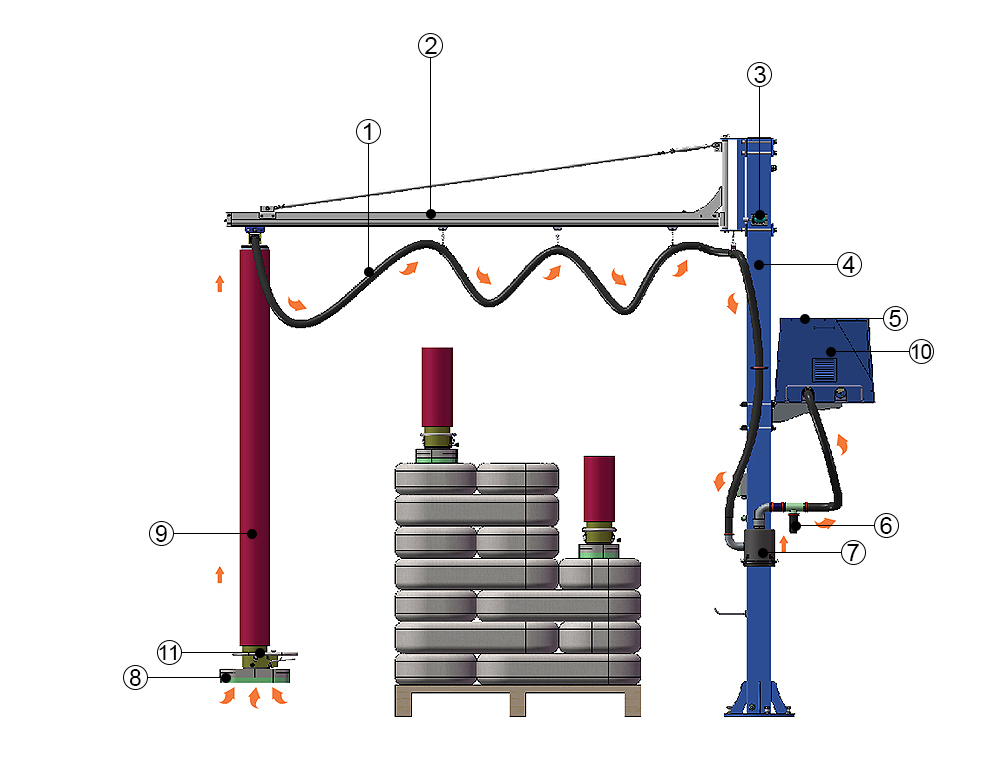

Parts and Structure

1. Air Hose

2. Rail

3. Rail Limit

4. Column

5. Silence Box (optional)

6. Pressure Release Valve

7. Filter

8. Suction Foot

9. Lifing Unit

10. Vacuum Pump

11. Control Handle

Models for Reference

Model | EST100 | EST120 | EST140 | EST160 | EST180 | EST200 | EST230 | EST250 | EST300 |

Suction Power | 30 | 50 | 60 | 70 | 90 | 120 | 140 | 200 | 300 |

Air Hose Length | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 |

Air Hose Diameter | 100 | 120 | 140 | 160 | 180 | 200 | 230 | 250 | 300 |

Lifting Speed | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s |

Lifting Height(mm) | 1800 | 1800 | 1800 | 1800 | 1800 | 1700 | 1700 | 1500 | 1500 |

Vacuum pump | 2.2Kw | 2.2Kw | 2.2Kw | 3Kw | 3Kw | 3Kw | 3Kw | 3Kw | 3Kw |

Working Object Description

When going off the assembly line, loading materials, palletizing, loading and unloading, you need to repeatedly carry some particularly heavy items. At this time, it would be wonderful if there was a device that could help you carry it easily and save time and labor costs.

Carrying packaging bags is one of the most important uses of vacuum tube lifters. It is widely used in food, pharmaceutical, chemical and other industries. The lifer is mainly used to lift bags containing sugar, salt, milk powder and other similar products. These bags can be made from a variety of materials, such as woven fabric, polyethylene or paper. Bags need to have a sturdy construction and a tight seal, or be breathable on the outside but have an airtight lining on the inside.

Precautions

When selecting and using a vacuum tube lifter, you need to pay attention to the following points. First, choose the appropriate model and specifications to ensure that it can meet actual needs. Secondly, during use, the safety and training of operators must be ensured to avoid safety accidents. In addition, the equipment must be inspected and maintained regularly to ensure the normal operation and service life of the equipment.

Application Scenario