- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

Vel140-RB-60

Product Description

Basic Info.

| Condition | New | Application | Use for handling Rubber Blocks, Baggages,Boxes,Bags | |

| Type | Vacuum lifter | Capacity | 15-300kg, Customized | |

| Up and Down Stroke | 100-1800mm, Customized | Working Radius | 3000mm, Customized | |

| Max Height | 3650mm, Customized | Basic Design | Sucking, Lifting | |

| Installation Form | Ground Installation, Customized | Specification | Customized | |

| Transport Package | Wood Box | Origin | China | |

| Trademark | Escott, or customized | Production Capacity | 100 pcs/Month |

General Introduction

This is a quick and convenient moving device that can help you move heavy items with ease.

The vacuum tube lifter is an efficient, safe and convenient automation equipment that is widely used in various industries, such as food, chemical, pharmaceutical, construction, machinery and other industries. The vacuum tube lifter uses a vacuum pump or vacuum blower as a vacuum source. The air flow inside the lifting unit can be adjusted through the control handle to control the contraction of the lifting unit, thereby controlling the up and down of items. The workpiece is transported to the designated location using a rail that can rotate 270 degrees and trolleys that can slide under the rail.

Vacuum suction lifter includes column, cantilever, vacuum pump, lifting air pipe, air guide pipe, filter and vacuum suction cup, and operating handle. The operating handle is used to control the opening and closing of the vacuum channel and the adjustment of the vacuum degree. It can be operated in a small space and needs to be controlled by a physically weak person. It can also adjust the vacuum adsorption force according to the weight of the lifted workpiece to improve the utilization rate.

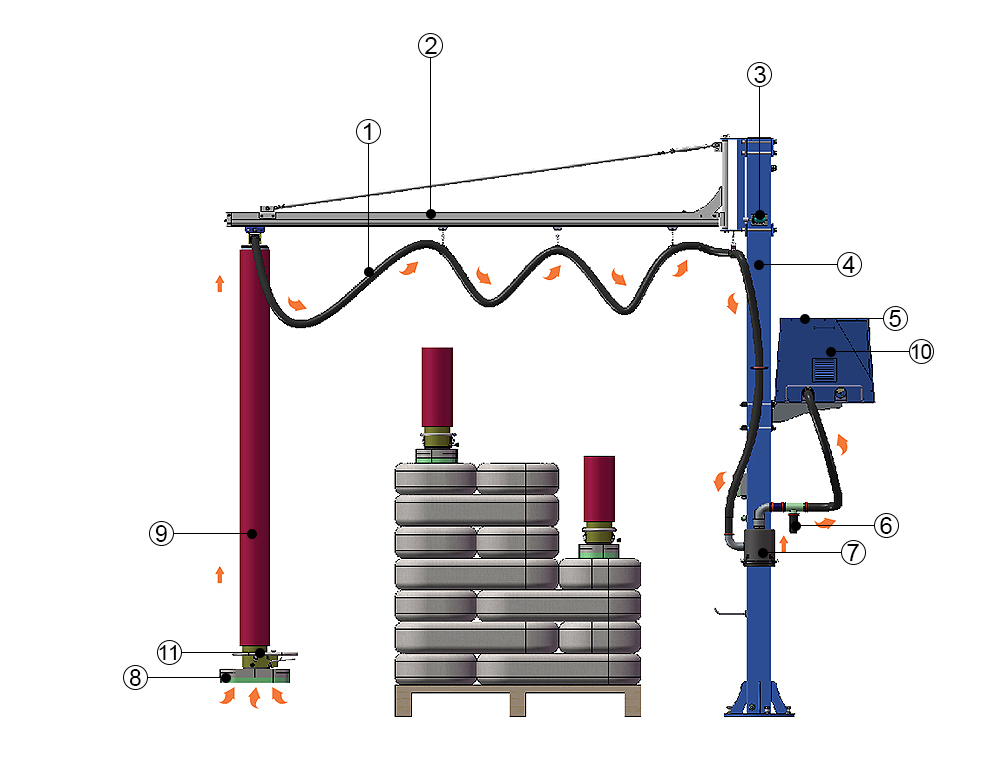

Parts and Structure

1. Air Hose

2. Rail

3. Rail Limit

4. Column

5. Silence Box (optional)

6. Pressure Release Valve

7. Filter

8. Suction Foot

9. Lifing Unit

10. Vacuum Pump

11. Control Handle

Models for Reference

Model | EST100 | EST120 | EST140 | EST160 | EST180 | EST200 | EST230 | EST250 | EST300 |

Suction Power | 30 | 50 | 60 | 70 | 90 | 120 | 140 | 200 | 300 |

Air Hose Length | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 |

Air Hose Diameter | 100 | 120 | 140 | 160 | 180 | 200 | 230 | 250 | 300 |

Lifting Speed | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s |

Lifting Height(mm) | 1800 | 1800 | 1800 | 1800 | 1800 | 1700 | 1700 | 1500 | 1500 |

Vacuum pump | 2.2Kw | 2.2Kw | 2.2Kw | 3Kw | 3Kw | 3Kw | 3Kw | 3Kw | 3Kw |

Working Object Description

Vacuum tube lifters are widely used in industries such as food, pharmaceutical, chemical, and construction industries. In fact, Vacuum tube lifters can do almost anything: whether you need to stack bags, boxes, barrels, stack rubber blocks, metal sheets or wooden boards, or move stone or furniture, vacuum cranes are your reliable choice. Vacuum tube lifter is easy to operate, highly efficient and reduces physical strain on workers.

Operation and Safty

The vacuum pump or blower is connected to the lifting unit through the connecting air hose. Control the handle switch, and once the suction cup touches the item, it will pick it up. The lifting unit then retracts and the weight of the load is supported by the vacuum. It can then be moved effortlessly. Pull the control stem up or down with your finger to raise or lower the workpiece, and pull the control stem down to the end to release the workpiece.

If a power outage occurs, anti-fall check valves allow items to slowly fall to the floor without the risk of slipping. If overloaded, the unit will not be able to lift the load.

Application Scenario