- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

Vel120-BL-50

Product Description

| Condition | New | Application | Use for handling Barrel ,Bucket | |

| Type | Vacuum lifter | Capacity | 15-300kg, Customized | |

| Up and Down Stroke | 100-1800mm, Customized | Working Radius | 3000mm, Customized | |

| Max Height | 3650mm, Customized | Basic Design | Sucking, Lifting | |

| Installation Form | Ground Installation, Customized | Specification | Customized | |

| Transport Package | Wood Box | Origin | China | |

| Trademark | Escott, or customized | Production Capacity | 100 pcs/Month |

The Vacuum Lifter System is a type of handling mechanism that utilizes the airflow to create a suction force in the air tube, which enables it to lift and transport objects. By employing the concept of vacuum lifting, it can easily absorb and move various workpieces. The workpiece is securely held, lowered, and released by manipulating a flexible control handle. This system ensures quick, secure, and efficient operation, reducing the need for manual labor.

Vacuum suction is to produce vacuum through a vacuum generator or vacuum pump, and after a certain capacity of the chamber produces vacuum, the corresponding material can be grasped. Even in the event of a power (electrical) failure, such as an unexpected power failure, it is still able to hold the adsorbed object firmly, and can be retained for a certain period of time for safe unloading and other safety measures.

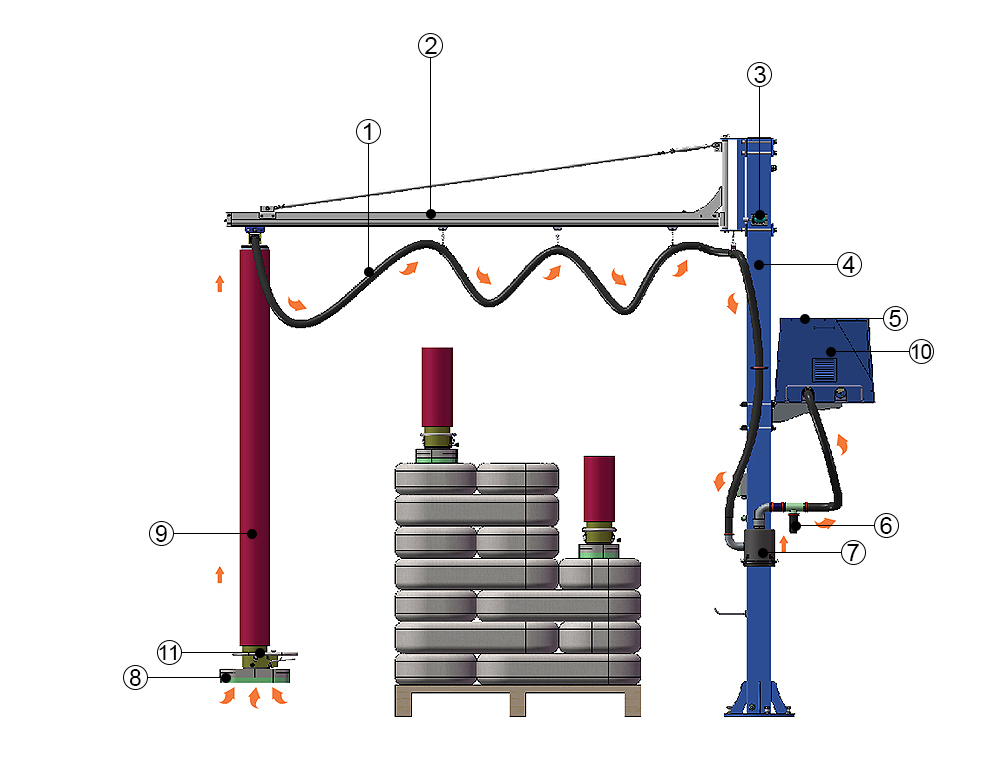

1. Air Hose

2. Rail

3. Rail Limit

4. Column

5. Silence Box (optional)

6. Pressure Release Valve

7. Filter

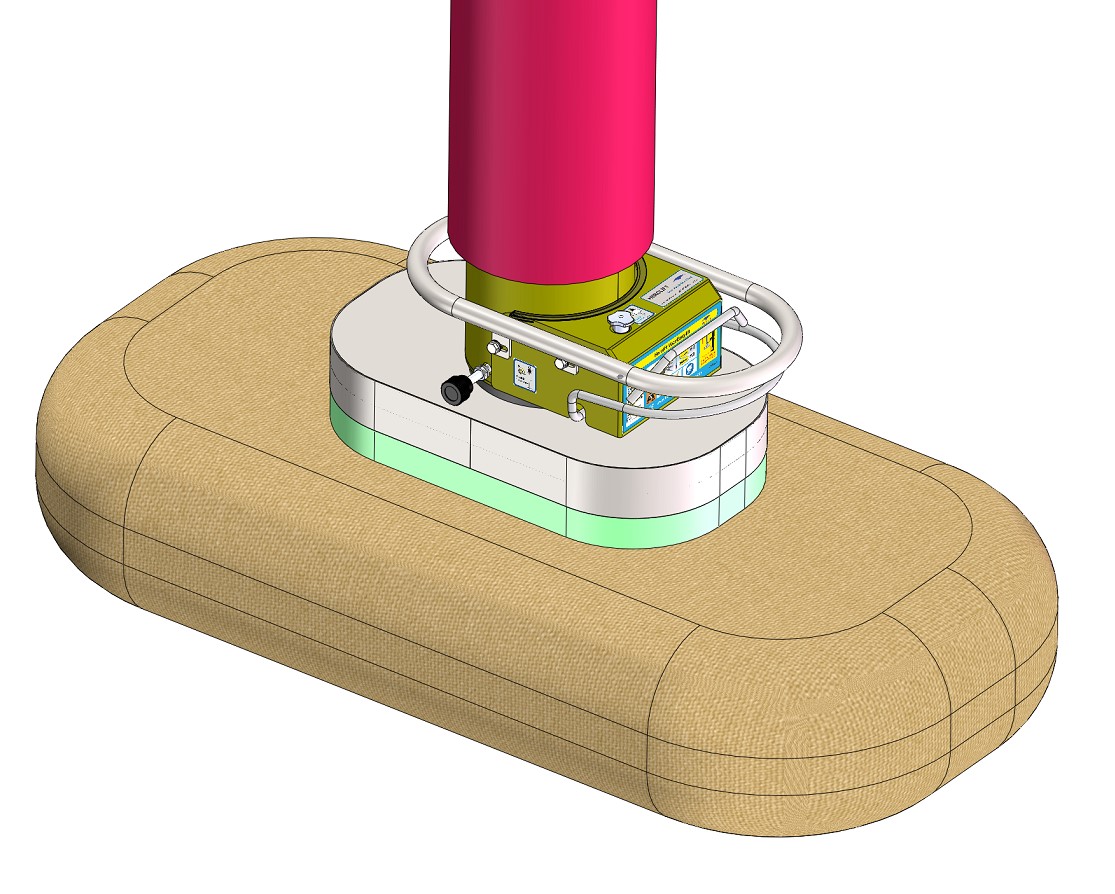

8. Suction Foot

9. Lifing Unit

10. Vacuum Pump

11. Control Handle

Models for Reference

Model | VEL100 | VEL120 | VEL140 | VEL160 | VEL180 | VEL200 | VEL230 | VEL250 | VEL300 |

Suction Power | 30 | 50 | 60 | 70 | 90 | 120 | 140 | 200 | 300 |

Air Hose Length | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 |

Air Hose Diameter | 100 | 120 | 140 | 160 | 180 | 200 | 230 | 250 | 300 |

Lifting Speed | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s |

Lifting Height(mm) | 1800 | 1800 | 1800 | 1800 | 1800 | 1700 | 1700 | 1500 | 1500 |

Vacuum pump | 2.2Kw | 2.2Kw | 2.2Kw | 3Kw | 3Kw | 3Kw | 3Kw | 3Kw | 3Kw |

Working Object Description

Vacuum lifters can be used for handling barrels or buckets. These devices use suction cups to grip the covers of the barrels or buckets. It is important for the middle section of the cover to be smooth. The choice of vacuum lifter is primarily determined by the weight of the barrel or bucket. As the weight increases, the lifting tube needs to be thicker and the suction cup size larger. Therefore, the size of the barrel or bucket cover must be compatible with the suction cup to ensure a proper fit.

Product Advantage

Vacuum lifters are widely used in various industries to ensure efficient material flow.

Its characteristics are: fast handling speed, wide industry coverage, and wide range of applicable products.

As a senior manufacturer in this industry, we have sufficient capabilities and customer experience to support us in providing you with the best products and services. We'll get your shipments processed faster and safer while protecting materials and your employees.

Depending on your needs, we can provide you with a complete customized solution, including handling systems and vacuum lifters designed to work perfectly with the system.

1.Lifting: finger upward pull the control valve stem, vacuum system negative pressure increase, lifting trachea contraction, workpiece lifting;

2. Lowering: finger downward control valve stem, vacuum system negative pressure reduction, lifting trachea elongation, workpiece decline;

3. Releasing: pull down the control valve stem to the end, the suction cup negative pressure is zero, the suction cup and the workpiece no suction, then the workpiece release;

|  |

We are a leading manufacturer specializing in innovative and reliable material handling solutions. With over 10 years of industry experience, our skilled team of engineers and technicians has developed a diverse range of handling machines,Our Product including:

- Lifting Equipment

- Pneumatic Rigid Arm Manipulators

- Vacuum Lifters

- JIB Cranes

- Overhead Cranes

- Intelligent Hoists

- Pneumatic Balance Cranes

- Customized Solutions for specific industries

Our commitment to quality and customer satisfaction has made us a trusted name in the industry. We prioritize building long-term partnerships with our clients by offering exceptional pre-sales and after-sales services. This includes comprehensive training, maintenance support, and prompt technical assistance, ensuring our customers maximize the value of our products and achieve their operational goals.

If you’re looking for a reliable partner in material handling, we invite you to connect with us.

Our professional team will work closely with you to deeply understand your needs, industry characteristics and application scenarios to ensure that the product design meets your expectations.

2. Customized design

According to your specifications and requirements, we provide flexible design solutions covering size, function and material selection to ensure the best performance of the final product.

3. High-quality production

We use advanced production technology and strict quality control to ensure that each customized product has excellent quality and reliability.

4. Fast delivery

We optimize the production process to quickly respond to customer needs and ensure that customized products are delivered on time within the agreed time.

5. After-sales support

We provide comprehensive technical support and maintenance services to ensure that the system continues to operate efficiently, and customers can get professional after-sales service and technical guidance at any time.

Q:Are you a manufacture or trading company?

A:We are the manufacturer, has more than ten years of production experience

Q: How long is your delivery time?

A: It is Usually 20 days after confirming the technical sheet and drawings.

Q: What is your price?

A: The price depends on your requirements for the equipment. Accordingto the model, the price is relatively different.

Q: What is the condition of your machine?

A: Brand new, can be customized.

Q:What is the guarantee of after-sales service?

A:Replacement parts within one year, lifelong technical guidance

Q:Mode of transportation?

A: You can choose sea, air, rail transportation (FOB, CIF, CFR, EXW, etc.)

Q:What problems can the roll handling manipulator solve?

A:1.Perform dangerous or heavy operations in place of humans

2.Improve production efficiency and quality

3.Reduce labor costs and so on