- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

EST160

Product Description

Basic Info.

| Condition | New | Application | Use for handling Barrel ,Bucket | |

| Type | Vacuum lifter | Capacity | 15-300kg, Customized | |

| Up and Down Stroke | 100-1800mm, Customized | Working Radius | 3000mm, Customized | |

| Max Height | 3650mm, Customized | Basic Design | Sucking, Lifting | |

| Installation Form | Ground Installation, Customized | Specification | Customized | |

| Transport Package | Wood Box | Origin | China | |

| Trademark | Escott, or customized | Production Capacity | 100 pcs/Month |

General Introduction

The vacuum tube lifter is a transportation system that uses the directional flow of air to generate negative pressure in the air tube and generate suction, thereby achieving suction and lifting and transportation processes. Manipulate the control handle to realize the suction cup's adsorption, descent and release of the workpiece.

Vacuum elevators are widely used in various industries, greatly saving manpower, improving work efficiency, and improving safety.

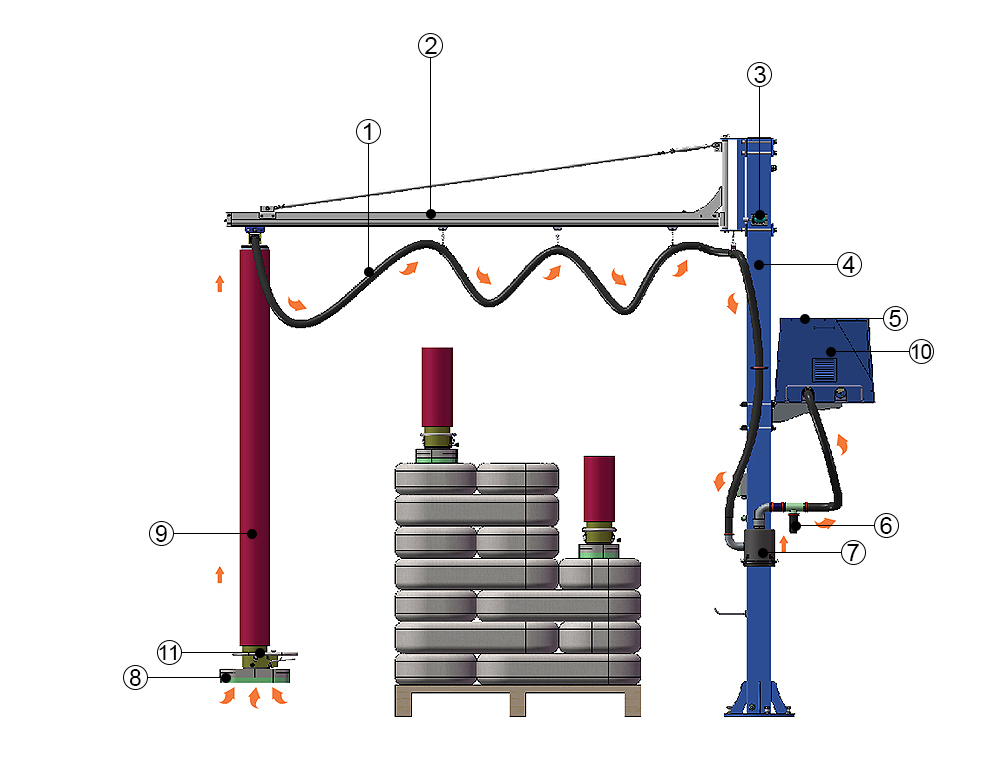

Parts and Structure

1. Air Hose

2. Rail

3. Rail Limit

4. Column

5. Silence Box (optional)

6. Pressure Release Valve

7. Filter

8. Suction Foot

9. Lifing Unit

10. Vacuum Pump

11. Control Handle

Models for Reference

Model | EST100 | EST120 | EST140 | EST160 | EST180 | EST200 | EST230 | EST250 | EST300 |

Suction Power | 30 | 50 | 60 | 70 | 90 | 120 | 140 | 200 | 300 |

Air Hose Length | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 |

Air Hose Diameter | 100 | 120 | 140 | 160 | 180 | 200 | 230 | 250 | 300 |

Lifting Speed | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s |

Lifting Height(mm) | 1800 | 1800 | 1800 | 1800 | 1800 | 1700 | 1700 | 1500 | 1500 |

Vacuum pump | 2.2Kw | 2.2Kw | 2.2Kw | 3Kw | 3Kw | 3Kw | 3Kw | 3Kw | 3Kw |

Working Object Description

Using a vacuum lifter for handling barrels or buckets is a common practice. This equipment employs a suction cup to securely grip the cover of the barrel . It is important for the center of the cover to have a smooth surface. The choice of vacuum lifter is primarily determined by the weight of the barrel being lifted. As the weight increases, the lifting tube becomes thicker and the suction cup size larger. Therefore, it is crucial for the size of the barrel cover to be compatible with the suction cup to ensure a proper fit.

Uses of Product

With the continuous development of modern industry, the machinery industry is also increasingly prosperous. Among them, as a new type of transport auxiliary machinery, tracheal suction crane is gradually receiving more and more attention.

The following are several specific application scenarios for vacuum lifter:

1. Packaging bags handling is the most common application of vacuum lifter. It is mainly used to suck sugar bags, salt bags, milk powder bags in the food and pharmaceutical industries, as well as various packaging bags in the chemical industry.

2. Cartons are often used for packaging products such as food, home appliances, and sanitary ware. Use a tracheal hoist to transport cartons, saving time and effort.

3. Barrels loading and unloading is another typical application of vacuum tube lifter.

4. Baggages handling reduces labor intensity and reduces labor.

5. This device can also be used to transport rubber blocks ,boards and chassis, using non-standard customized suction cups to ensure reliable and safe adsorption.

Application Scenario