- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

EST160

Product Description

Basic Info.

| Condition | New | Application | Use for handling bags,sacks | |

| Type | Vacuum lifter | Capacity | 15-300kg, Customized | |

| Up and Down Stroke | 100-1800mm, Customized | Working Radius | 3000mm, Customized | |

| Max Height | 3650mm, Customized | Basic Design | Sucking, Lifting | |

| Installation Form | Ground Installation, Customized | Specification | Customized | |

| Transport Package | Wood Box | Origin | China | |

| Trademark | Escott, or customized | Production Capacity | 100 pcs/Month |

General Introduction

A vacuum lifting system is a system that uses the directional flow of air to create negative pressure in the air tube, thereby generating suction.The object only needs a force of vacuum suction obtained by the vacuum pump to carry the object, and it does not need other power. The operator simply uses the control handle to control the amount of vacuum in the system. When a suction pad is placed on an object, the suction pad absorbs the object. The more vacuum, the higher the object is lifted, the less vacuum, and the object will be slowly lowered. The operation mode is simple and efficient.

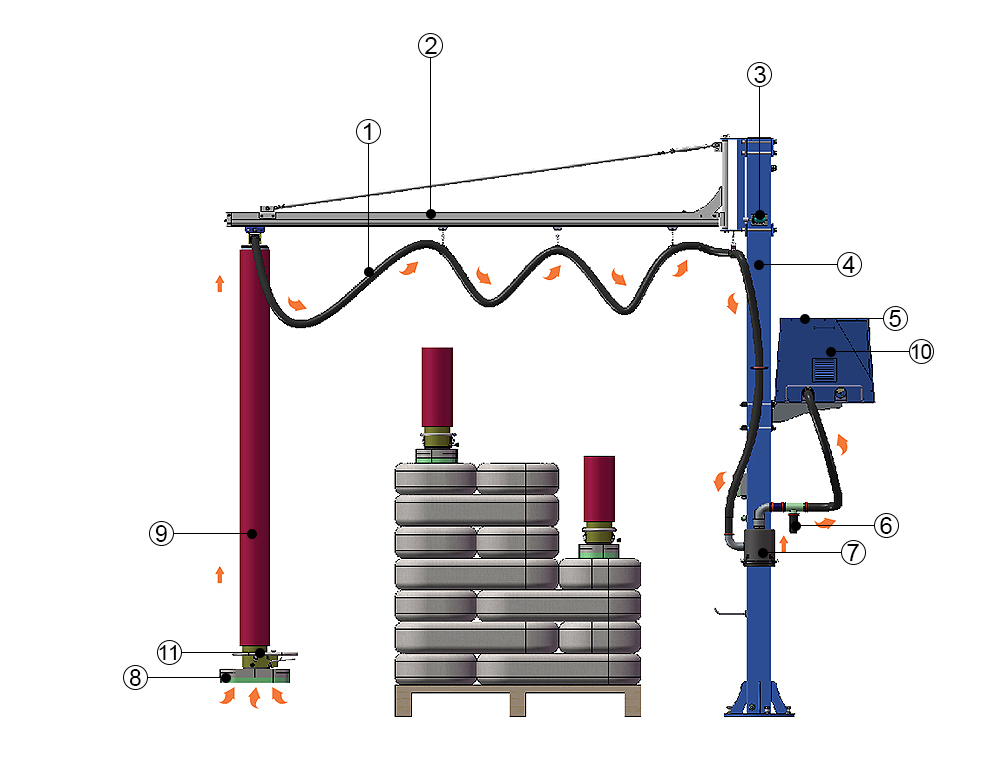

Parts and Structure

1. Air Hose

2. Rail

3. Rail Limit

4. Column

5. Silence Box (optional)

6. Pressure Release Valve

7. Filter

8. Suction Foot

9. Lifing Unit

10. Vacuum Pump

11. Control Handle

Models for Reference

Model | EST100 | EST120 | EST140 | EST160 | EST180 | EST200 | EST230 | EST250 | EST300 |

Suction Power | 30 | 50 | 60 | 70 | 90 | 120 | 140 | 200 | 300 |

Air Hose Length | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 |

Air Hose Diameter | 100 | 120 | 140 | 160 | 180 | 200 | 230 | 250 | 300 |

Lifting Speed | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s | appr.1m/s |

Lifting Height(mm) | 1800 | 1800 | 1800 | 1800 | 1800 | 1700 | 1700 | 1500 | 1500 |

Vacuum pump | 2.2Kw | 2.2Kw | 2.2Kw | 3Kw | 3Kw | 3Kw | 3Kw | 3Kw | 3Kw |

Working Object Description

Vacuum tube lifter can be used to handing bags. This is also one of the main uses of the vacuum lifter. This kind of machines are widely used in food, pharmaceutical, chemical, construction and other industries. They are used to lift bags containing sugar, salt, rice, milk powder, detergent, laundry powder, fireproof materials, etc. The bags are made of different materials, including woven fabric, polyethylene (PE), and paper. The bag must be of sufficient strength and the surface must either be tightly sealed. Our equipment is used by companies in a wide range of industries and has received high ratings.

Advantage of product

Vacuum tube lifters can do almost anything: whether you need to stack bags, boxes, or load barrels onto a truck, stack metal sheets or wooden boards, or move stone or furniture. Moving with a vacuum lifter will always be your best moving solution. Carrying with a vacuum lifter is simple to operate, faster to carry, more ergonomic and safer, and reduces the possibility of workers' physical strain and work-related injuries, which also improves employees' motivation and production quality.

Application Scenario